Beginning a t- shirt company starts with finding the optimal tshirt printing process. The negative side is that there is more than one right response.

Several considerations determine the best printing technique for your tshirt printing business, the type of fabric, tshirt volume, your design vision, and your financial and time limitations.

Would you, for instance, like to print the shirts yourself and purchase your own equipment? Rather, would you like a print on demand service to fulfill your orders? If you select the dropshipping business model, suppliers will even deliver your orders under your label.

This post will look at the best method for printing t-shirts for personalizing your own shirts or creating designs for sale.

We will go over each shirt printing alternative’s benefits and drawbacks, so you can make an educated decision.

Table of Contents

Toggle1. Direct To Garment Printing

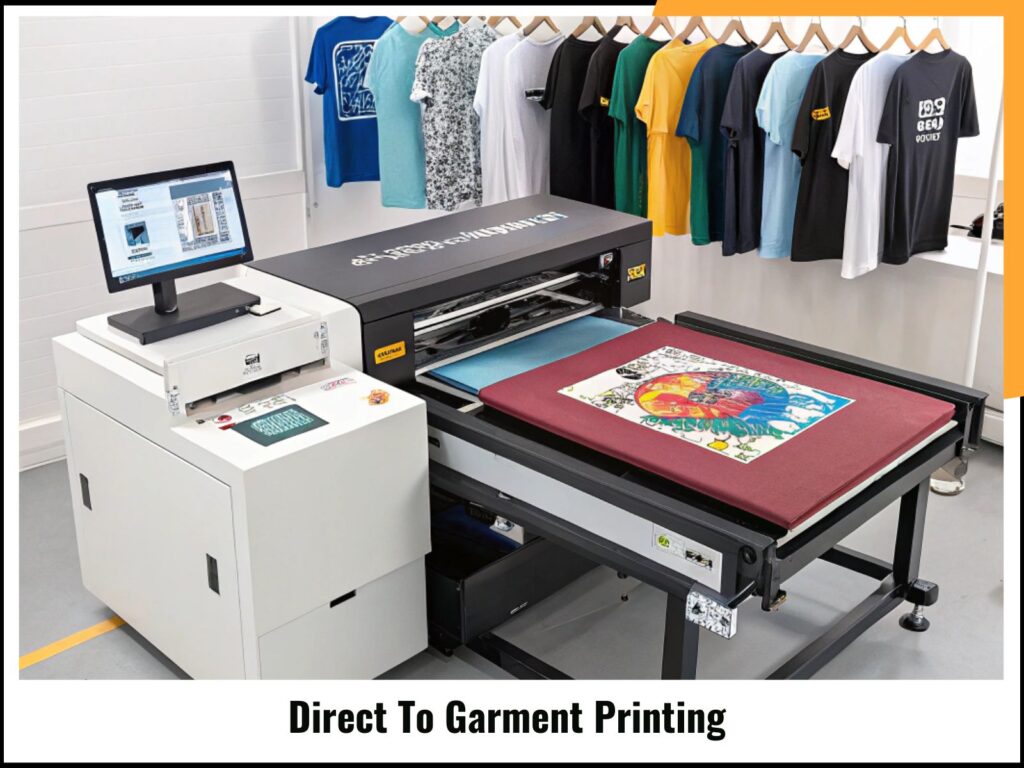

DTG, or direct to garment printing, is currently among the most widely used t shirt printing methods on the market. It is also more recent than some of the other techniques discussed here.

How does DTG work?

The simplest way to describe garment DTG printing is to say that it is printing on cloth rather than on paper.

This indicates that the ink is jetted straight on the material to produce the design, exactly as it does on your personal print at your home desk.

There is, however, a further important stage distinct from paper prints.

Printing on fabric with DTG demands the item to be pretreated before the ink is added. This ensures that the fibers of the garment will hold onto the ink.

One Off printing is made possible by the DTG tshirt printing process. This is why this printing process is ideal for smaller companies looking to make custom t-shirts (or custom garments in general) and lacking a high quantity of orders.

With the DTG tshirt printing process, you may experiment with several designs and sell on demand without having lots of shirts on stock. And you will still have excellent t shirt printing.

DTG Printers

To produce t-shirts using DTG, you’ll have to have a DTG printer with unique water based inks that can bond with the fabric ideally composed of cotton or high cotton content.

Depending on your chosen process, the machine (or machines) spreads a pretreatment solution over the surface of the textile. Next, the ink is jetted onto the pretreated surface, hence generating a printed pattern in only minutes.

Given its high cost, if you intend to purchase your personal equipment, plan for a major initial expenditure.

You could instead depend on a print on demand company like Printful, which has high quality equipment and is prepared to print your t shirts once an order comes in.

Once you link your online store to Printful, we will automatically fill, pack, and ship your order to your customer for you.

Fabric compatibility

Though DTG printing is also appropriate for cotton mixes, it is most effective on 100% cotton garments. As DTG chemistry is usually not intended for them, artificial fibers are not suggested.

A white under base is always printed on these textiles to give a neutral base for the next colors printed on top since dark materials can absorb the lighter ink colors.

This ensures that the colors of your design remain brilliant and precisely shown.

This printing process calls for pre and post treatments as well as special care advice to guarantee product longevity.

Advantages

- Nothing found either in films or meshes

- Straightforward and effective procedure.

- Permits one offs.

- Great fit for small to medium enterprises

- Frequently, more sustainable than screen printing is a more sustainable technique since it prevents excessive overproduction and minimal waste results.

- Permanent prints

- High quality output and accuracy for sophisticated designs

- Softtouch and breathable

- There are practically no color restrictions with usually brilliant results.

Disadvantages

- Needs expensive tools that demand special maintenance and knowhow

- Because of the wide variety of colors available, it is difficult to exactly match a highly particular style color.

- Requires post treatment and pretreatment.

- A poor alternative for many massive orders using the same layout

- Not good on non cotton textiles.

Most suitable for cotton based clothes you want to print on, DTG printing is perfect for more sophisticated, detailed designs with endless colors and subtleties.

It can handle almost any complexity of design—from simplicity to complexity. Moreover, it yields very accurate, top quality prints well suited for artistic pictures or designs.

2. DTF (Direct-To-Film) Printing (or PET Film Transfer Printing)

One of the most adaptable tshirt printing techniques in the business, DTF is short for direct film printing.

Unlike before, this tshirt printing approach calls for a film to carry the design to your shirt. One can use several kinds of fabric for the process.

What Exactly Is DTF doing?

The layout is initially printed on a unique PET film using water based inks and a powder intended to facilitate design transfer in DTF printing. This is followed by printing on the shirt.

Using a heat press machine, the film peels off as the transfer is completed from one surface to another, leaving a precise print on the apparel.

DTF Machines

Printing a tshirt using the DTF technique would require not only equipment like a heat press machine but also, in terms of materials, film and powder plus the pre and post treatments for long lasting and top quality prints.

Fabric Compatibility

Compared to other tshirt printing techniques, DTF printing has many benefits. It can be used on a wider range of fabrics including cotton, polyester, fleece, nylon, and mixed materials.

Advantages of This Approach

- Good outcomes for complex prints

- More colors and shades are allowed by this (for instance, it doesn’t call for separate layers for colors or design elements like screen printing).

- Works with various kinds of fabric

Disadvantages

- More steps means less rate of progression.

- Greater cost for powders and materials (PET film and powder) machine

- The films are not environmentally friendly; they create more trash.

- More thickly printed than DTG

- Elements that are transparent do not work well.

DTF printing, like DTG, is the ideal solution for intricate designs with many colors and small details. For people who want to make many t shirts with the same design, it is also wonderful.

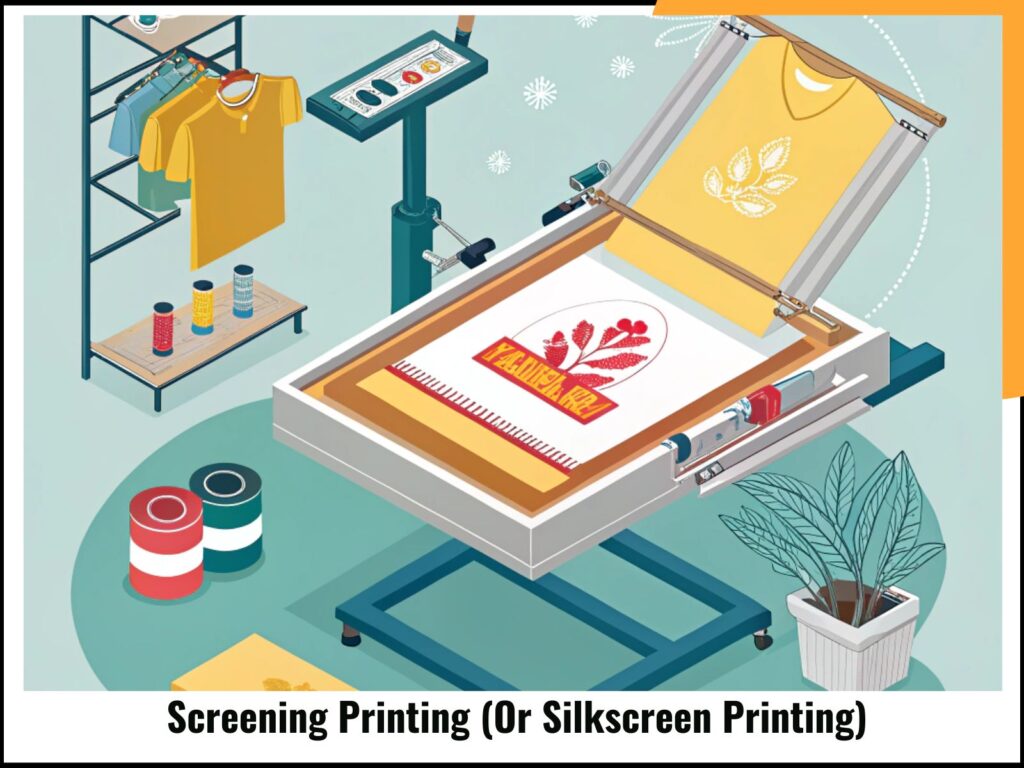

3. Screening Printing (Or Silkscreen Printing)

One of the oldest t shirt printing techniques available is screen printing, also known as silk screen printing. And also one of the most effective! Screen printing provides bright, long lasting t shirt graphics at reasonable cost.

How Screen Printing Work?

Screen printing transfers your design to the tshirt using a stencil (acting as a template), a mesh screen, and a squeegee or straight blade.

The pattern is first stenciled and mounted on a mesh screen. Blocking every region not to be designed helps the tattoo to go just on the open spaces.

The ink is poured onto the mesh and then using the squeegee or blade pressed to replicate the pattern on the material once the stencil is located. Excess ink is wiped off next, and the tshirt is placed out flat to dry.

Machine Screen Printing

Though it seems like a manual activity, there are screen printing equipment made to streamline the process and let you scale your own printing company. This is, however, the machine and supplies you will need in case you plan to begin small:

A computer having the vital programs for readying your designs

An inkjet printer to make the film positive that will make the stencil.

Depending on how many different kinds of artwork you will use, screens made of a fine mesh stretched over a frame might need several sheets of mesh. clean room with safe lighting head or screen drying cabinet.

Fabric Compatibility

For screen printing, natural materials such as wool, silk, and cotton works best. Although natural and artificial mixtures can also be screen printed using this approach, you should steer clear of 100% synthetic mixtures like spandex, polyester, and lycra.

Advantages

- Long Lasting prints of excellent quality.

- Cost efficiency for more great orders

- It goes well with many various materials.

- Rapid and cost effective for several identical designs (25 pieces per design on average)

- With any type of written material, it helps to have fresh eyes and to take it slowly.

Disadvantages

- A long process, not suitable for small companies seeking ondemand sales.

- Not best for complex patterns.

- Restricted color range

- For minor orders and designs with multiple colors, it is cost prohibitive.

The methanol based (non biodegradable) screen printing ink is not particularly eco friendly since the process consumes water.

One Color designs and larger companies demanding mass production benefit from this t shirt printing technique. For orders that are less in complexity, digital printing is the more practical approach.

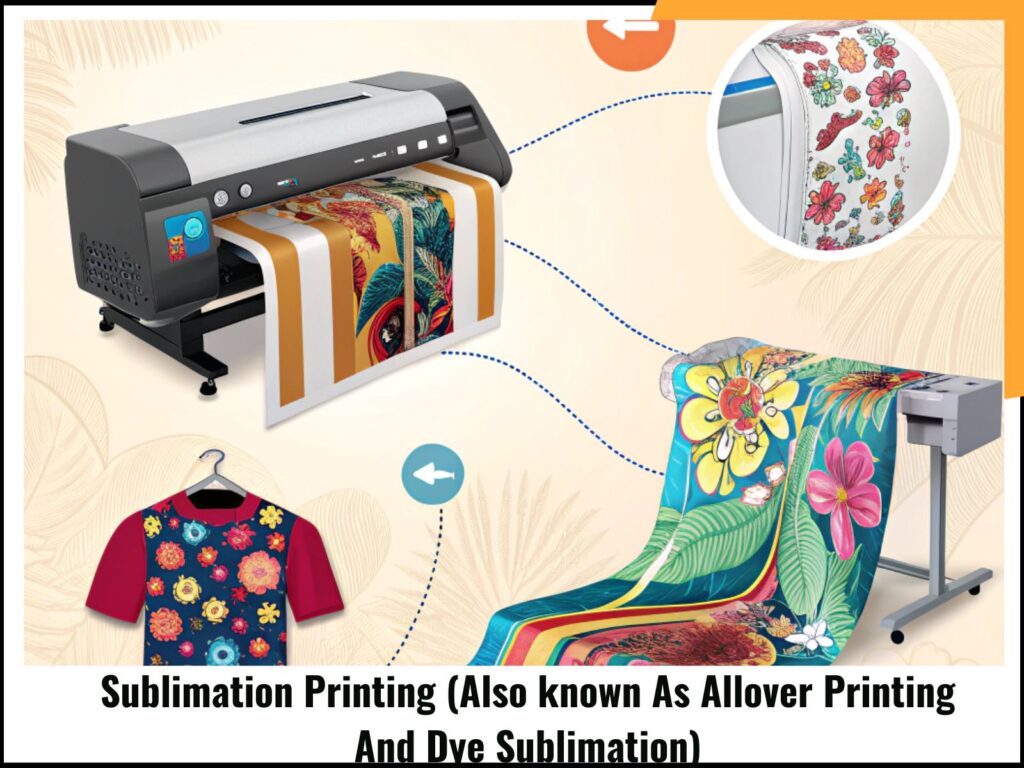

4. Sublimation Printing (Also known As Allover Printing And Dye Sublimation)

Sublimation is the transformation of a solid material under high pressures and temperature to gas. Then this printing method got its name: it was believed that the dye turned to gas during printing.

Although the original term is still commonly used along with the technically correct one—dye diffusion—it is now known that the dye has some liquefaction.

The material in this printing technique is a unique kind of liquid dye that permeates the material to produce vibrant patterns by changing not just its color but also its texture.

Sublimation printing, known as dye sublimation or digital sublimation, therefore works well for garment printing.

Actually, it has become among the most common techniques for companies marketing tshirts, particularly allover print ones.

How Sublimation Printing Works?

Printing is rather straightforward. Print first the design onto special heat transfer paper. Apply heat to the transfer paper next so the tshirt’s ink will permeate.

Sublimation Equipment

Sublimated tshirts are produced by means of a heat transfer printing machine (a heat press machine or sublimation printer) using the specific transfer paper and ink.

Watch the material when using older printers to guarantee it doesn’t crease while printing.

This only arises if the material and the paper are not in sync; something you don’t have to concern about in more recent models.

Material Suitability

Forget sublimation if you have ideas of using cotton tshirts. This process is designed for artificial textiles like polyester.

All Over printing, or dye sublimation, is ideal for all over print tshirts. However, for large orders, it is not the cheapest printing technique since the printed design has to be on transference paper every time a fresh tee is produced.

This would better fit ondemand manufacturing.

5. Additional T Shirt Printing Techniques

Next tshirt printing alternatives need to be investigated now that we have covered the fundamentals of the most popular printing methods available. Who knows? Maybe the textile printing solution you have been searching is outside of the mainstream.

Sublimation Printing

Though they would fit under the screen printing heading, plastisol transfers include one more step: the application of the design on a unique printing paper.

Plastisol transfers work how?

The first step in the process is just like screen printing—a mesh screen and a stencil are employed. Rather than printing right on the fabric, the design is first printed digitally on plastisol transfer paper, which is then used with a heat press to print on your tshirt.

Though this extra step makes the process appropriate for a set of particular requirements, the primary one is that plastisol transfer lets you get ready for tshirt printing ahead of time.

You prepare the transfer paper once and then in a quick, easy way you can print the design on a piece of clothing whenever you want.

Heat Pressed Printing

Starting your printing journey in this manner is most likely the least costly. You only need special printing papers, a typical inkjet printer, and a fairly inexpensive heatpress device.

How Does Heat Press Printing Function?

Though the technical side of everything is somewhat different, in many respects it resembles dye sublimation. The design is first printed onto transfer paper in each technique and then applied onto the material under heat and pressure. Using the heat press technique, the design sticks on the cloth to produce a top layer over the tee. The ink becomes fabric with dye sublimation, essentially coloring the shirt.

Advantages

- Definitely the least costly means possible around

- Nothing hard or complex

- Just right for intricate patterns and modest amounts.

Pros and carried

- Not ideal for heat sensitive fabrics.

- Poor outcomes on darker textiles

Vinyl cutting (otherwise vinyl printing)

Versatile application of the heat press method, vinyl cutting—or vinyl printing—works well for low quantities as well as for mass printing.

How Does Vinyl Cutting/Vinyl Printing Work In Operation?

The design is first cut from a vinyl sheet using a laser cutter and computeraided design (CAD) software. After that, a heat press machine moves the design to the tshirt. A lively, topquality print is the outcome of your selection among many vinyl colors.

The drawback is that it tends to cause the fabric to lose flexibility, so vinyl printing is more ideal for tiny prints including branding, icons, or text.

Benefits

- Reliable and topnotch outputs.

- Flexible approach—suitable for big and small volumes

Cons

- Depends on added hardware (the vinyl cutter).

- Unfit for large prints.

Discharge printable

Almost like a reverse tshirt printing approach is this one: instead of adding ink to the tshirt, you remove the fabric’s dye to produce a negative print. Though not the most adaptable tshirt printing technique, the outcome is a distinctive, old appearance print.

What is the process of discharge printing?

Only natural fibers (cotton) will support discharge t аssistant printing. The fabric color also affects; some colors will fade better than others. The design can be applied to the tshirt using screen printing; the ink is, however, combined with a special product meant to remove the original dye and replace it with your chosen color.

Benefits

Prints with bright colors and soft to the touch feel

Good for easy and difficult designs

particular retro effect

Cons

Works exclusively with natural fibers

Results vary—prints might have different colors.

Belt printed

Including the sleeves and collar, this approach lets you use your design all over the shirt. While the outcome is a smooth allover print, the method is not the most cost efficient one; therefore, this approach is not usually seen in retail.

What is belt printing all about?

Similar to screen printing, a belt printing equipment transfers the design onto a roll of material. Normally, the fabric is kept soft by a one color design. Along with other methods including conventional screen printing, this one can be used to enhance the layout. The shirt is made by cutting the roll of fabric once published.

At last, let’s cover more conventional customizing techniques which don’t always call for equipment and enable homemade modification.

This is the method underpinning the well known tie dye effect. The concept is to stop the ink from touching a few parts of the fabric, therefore producing a rough look as the finished product. With tie dye, sections of the material are knotted together before being plunged in dye. Older conventional methods including shibori and bandhani follow the same route.

Apart from tying and clamping, you can also employ chemical products such as waxes to stop the ink from seeping regions of the cloth.

Airbrushing

This could be a very enjoyable tshirt printing choice for you if you like to create and play around. Airbrushing, which although technically challenging, produces very distinct effects reminiscent of graffiti. With an airbrush gun, paint, and a stencil, the process is simple; you are equipped to start working.

Since not every material and color works this way, first run a test. It’s also worth noting that airbrush prints are not long lasting; the ink will wear off with time. Apart from that, this approach can assist you to produce highly original designs.

Conclusion

Choosing the best method for printing T-shirts depends on your needs, budget, and the type of design you want to achieve. Screen printing is the go-to option for bulk orders and durability, while DTG is perfect for detailed, full-color prints on cotton garments.

If you need versatility across various fabrics, DTF printing is a strong contender. Sublimation works best for polyester and vibrant, all-over designs, while heat transfer methods offer affordability and accessibility for small-scale projects.

By understanding the strengths and limitations of each technique, you can select the best option to ensure high-quality prints that meet your business or personal needs.

FAQ: Best Method For Printing T-Shirts

Q1: What is the best method for printing T-shirts?

The best method for printing T-shirts depends on your needs. Screen printing is ideal for bulk orders and durability, while DTG (Direct-to-Garment) printing works best for detailed, colorful designs on demand. Heat transfer and sublimation are great for smaller batches and vibrant prints. If you need high quality with a soft feel, DTF (Direct-to-Film) is a growing favorite.

Q2: Which T-shirt printing method lasts the longest?

Screen printing is the most durable method because the ink bonds deeply with the fabric. If properly cured, the design can last for years without fading or cracking. Sublimation printing is also long-lasting but works best on polyester.

Q3: What is the most cost-effective T-shirt printing method?

For large orders, screen printing is the most cost-effective because the cost per shirt decreases as the quantity increases. For small batches or one-off prints, DTG printing or heat transfer vinyl (HTV) can be more affordable since they don’t require setup costs.

Q4: Which printing method is best for full-color designs?

DTG printing and sublimation are the best choices for full-color designs with gradients and fine details. DTF printing is another excellent option, as it works on various fabrics while maintaining high detail and vibrant colors.

Q5: Can I print T-shirts at home?

Yes! The easiest methods for home printing are heat transfer vinyl (HTV) with a heat press or sublimation printing if you have a sublimation printer. Inkjet and laser heat transfers also work but may not be as durable as professional methods.

Q6: What fabrics work best for T-shirt printing?

- Cotton – Best for screen printing, DTG, and DTF due to ink absorption.

- Polyester – Ideal for sublimation printing since it bonds with the fibers.

- Blends (Cotton-Polyester) – Work well with DTF and heat transfer methods.

Q7: Why does my T-shirt print fade after washing?

Fading happens due to improper curing, low-quality ink, or incorrect washing techniques. To prevent this:

- Wash in cold water and inside out.

- Use mild detergent and avoid bleach.

- Tumble dry on low or air dry to extend print life.

Q8: Is DTG better than screen printing?

It depends on your needs:

- DTG printing is better for detailed, colorful, and small-batch prints.

- Screen printing is best for bulk orders and solid color designs.

If you need flexibility and a soft feel, DTG is ideal. If you need durability for bulk production, go with screen printing.

Q9: What is the difference between heat transfer and sublimation?

- Heat transfer applies a printed design onto fabric using heat and pressure. Works on many fabric types.

- Sublimation infuses ink into polyester fabric for a vibrant, long-lasting print but only works on light-colored polyester.

Q10: How do I choose the right T-shirt printing method for my business?

Consider:

- Order size – Screen printing for bulk, DTG/DTF for small orders.

- Fabric type – Cotton (DTG, DTF, screen print), Polyester (sublimation).

- Design complexity – Full-color = DTG or sublimation; Simple logos = Screen printing.

- Budget – Heat transfer or DTG for low-cost small batches, Screen printing for high-volume orders.

Q11: Where can I get custom T-shirts printed?

You can order custom T-shirts from print-on-demand services like Printful, Printify, or local print shops. If you’re printing in bulk, look for screen printing companies that offer wholesale pricing.

Q12: What are common T-shirt printing mistakes and how to avoid them?

- Low-quality images – Use high-resolution (300 DPI) designs.

- Wrong fabric choice – Match the printing method to fabric type.

- Poor heat settings – Follow the recommended temperature and pressure for transfers.

- Not curing ink properly – For screen printing, ensure proper curing to avoid peeling or fading.

Q13: How do I care for printed T-shirts to make them last longer?

- Wash in cold water, inside out.

- Use gentle detergent and avoid fabric softeners.

- Tumble dry low or air dry.

- Never iron directly on the print.

Q14: What’s the best printing method for dark-colored T-shirts?

Screen printing, DTF, and heat transfer vinyl (HTV) are great for dark shirts. DTG can work but requires a white underbase, making the process more expensive.