Heat transfer printing is a process of historical and modern innovative techniques.

It has been started since the 18th century and used with heated metal plates for ink-transfer.

During the 1950 and 1960s the most popular processes were heat-transfer decals and iron-on transfer for DIY clothing customization.

Since the 1980s the introduction of vibrant designs on T-shirts and athletic wear had been the sources of attraction.

In the 90s digital technology became popular and gave way to high quality images on different stuff.

This advanced color printing and material compatibility for fabric and paper.

From screen printing to modern techniques, material compatibility and process equipment are essential.

Heat transfer printing remains key to customization and creative expression.

Table of Contents

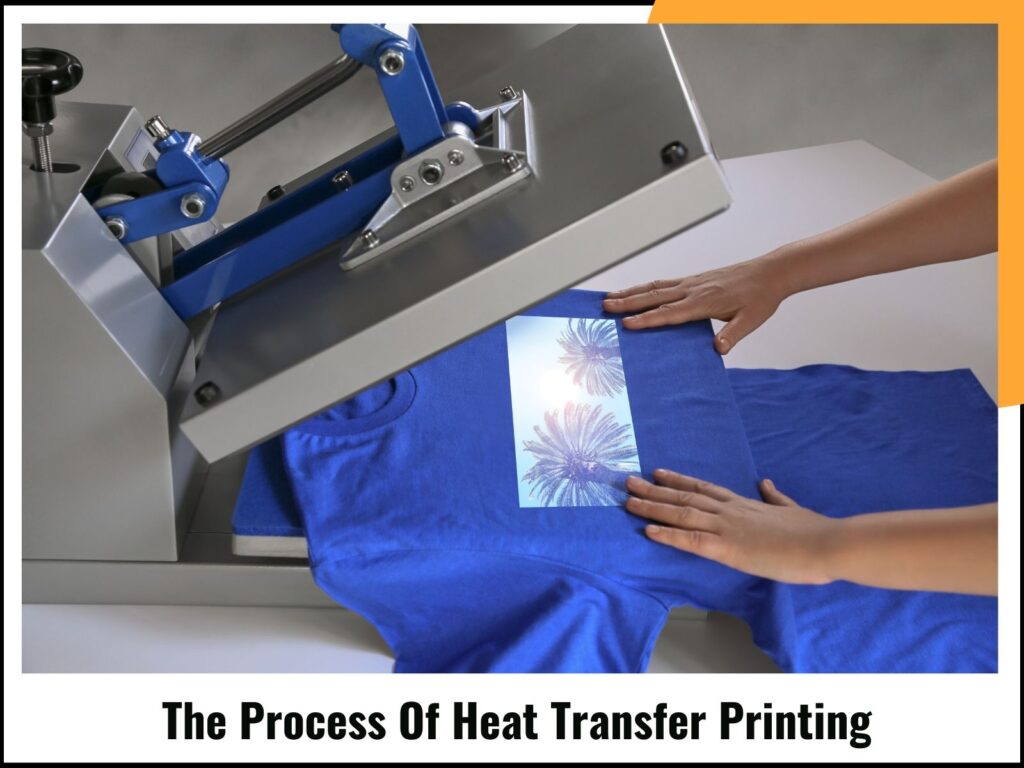

ToggleThe Process Of Heat Transfer Printing

Heat transfer printing is a fascinating method that seamlessly combines design and technology to decorate items such as T-shirts, mugs, and bags.

Using special paper or film, along with inks tailored to the material compatibility, this process ensures precise and vibrant results.

A heat press machine, functioning like an advanced iron, applies controlled heat and pressure, transferring printed images onto various surfaces.

The process begins with designs crafted on transfer paper using special ink, which is then placed carefully onto the chosen material.

The combination of heat and pressure activates the ink, embedding the design onto the item.

Whether working with a simple design or experimenting with intricate details, the success of the transfer process lies in understanding the interaction between the machine, paper, and material.

Types Of Heat Transfer Printing

Heat transfer printing offers a variety of techniques to cater to different materials and designs, each with unique advantages.

Vinyl heat transfer is ideal for simple designs or text and works well on T-shirts, caps, and bags, using vinyl sheets that are cut and pressed onto the fabric.

Screen-printed heat transfer excels in creating vibrant and textual designs, requiring transfer paper and a screen printer for accuracy.

Sublimation uses dye-sublimation ink and sublimation paper to achieve photorealistic images, making it perfect for mugs, shirts, or phone cases, especially on polyester or polyester-coated items.

Direct-to-film heat transfer is a versatile option, compatible with DTF printers and inkjet printers, offering high detail and fine touches on a range of materials, including wood and metal.

Each method highlights the importance of using suitable materials, ensuring finishes that are smooth, slightly raised, or textured, with high wash ability for long-lasting durability.

| Feature | Vinyl Heat Transfer | Screen-Printed Heat Transfer | Sublimation Heat Transfer | Direct-to-Film (DTF) Heat Transfer |

| Print Process | Cutting and pressing vinyl | Screen printing on transfer paper and heat pressing | Printing onto sublimation paper and heat pressing | Printing directly onto film and heat pressing |

| Transfer Paper/Film Type | Vinyl sheets | Transfer paper | Sublimation paper | PET film |

| Printer Compatibility | Vinyl cutter | Screen printer | Sublimation printer | DTF printer / Inkjet printer |

| Ink Type | NA | Plastisol ink | Dye-sublimation ink | Pigment ink |

| Suitable Material | T-shirts, bags, caps | T-shirts, bags, textiles | Mugs, shirts, phone cases | T-shirts, bags, caps, wood, metal |

| Fabric Type | Most fabrics | All fabrics | Polyester or polyester-coated items | All fabrics |

| Detail Level | Simple designs, text | Vibrant designs, textual designs | Full-color, photorealistic images | Photorealistic images, fine details |

| Touch Feeling | Slightly raised | Slightly raised and textured | Smooth (feels like part of the material) | Slightly rubbery |

| Wash ability | High | High | High | High |

1. Vinyl Heat Transfer (HTV)

Vinyl heat transfer involves cutting a design outline from vinyl, applying heat, and transferring it onto a material.

This process is often used for simple designs, such as textual graphics, names, numbers, and logos on T-shirts.

The ease of use makes it perfect for single-colored designs, though printable heat transfer vinyl (HTV) allows for multi-color, detailed, and vibrant images to be printed, cut, and transferred onto fabrics using a heat press.

The transfer process provides an expanded range of possibilities, making it ideal for both basic and more intricate designs, enhancing the versatility of vinyl heat transfer.

2. Sublimation Heat Transfer

Sublimation heat transfer stands out when printing full-colored, realistic picture images on synthetic fabrics.

This method involves using sublimation ink, a type of dye that transforms into gas when heated.

The design is printed onto special paper with a sublimation printer, such as the Epson Sure Color Series, before being applied to the item using a heat press machine.

When pressure and heat are applied, the sublimation ink turns into gas and seeps into the material.

Once it cools, the gas solidifies, ensuring the design becomes a permanent part of the fabric, rather than simply sitting on top.

This technique offers vibrant, long-lasting designs that won’t peel or fade, but it works best on polyester fabrics or items with a special coating to accept sublimation ink.

3. Screen Printed Heat Transfer

Screen-printed heat transfer uses a manual screen printing technique to create vibrant designs directly on transfer films, often incorporating plastisol ink.

The printed designs are then heat pressed onto various fabrics, ensuring the top layer adheres firmly to the material’s surface.

This method is ideal for adding textured details and works well across multiple materials.

Pre-made heat transfer decals are also available, offering a convenient solution for applying designs to garments or other items.

The process ensures a noticeable touch, making screen printing a versatile and reliable choice for high-quality heat transfers.

4. DTF Heat Transfer

DTF heat transfer is a modern method where designs are printed directly onto a specialized film using a DTF or inkjet printer.

This process uses water-based pigments for high-quality, vibrant colors. The printed design is then coated with thermally activated adhesive powder, which bonds to the wet ink.

The film undergoes a curing stage, where the powder is melted at a specific temperature to ensure optimal adhesion.

Once cured, the transfer film is heat-pressed onto various substrates, including light and dark fabrics like T-shirts, hoodies, and even accessories like bags and shoes.

The controlled heat and pressure help the design to firmly adhere to the material, leaving a durable print.

This method is especially advantageous for custom apparel because it doesn’t require pre-treatment, making it ideal for creating unique designs on a wide range of products.

Required Equipment In The Process Of Heat Transfer Printing

Alongside the presence of heat transfer paper and ink, additional equipment required are listed as follows:

1. Heat Transfer Printer

In the world of heat transfer printing, selecting the right printer for your method is essential for achieving high-quality results.

For Direct-to-Film (DTF) printing, a specialized DTF printer, often an inkjet printer capable of handling pigment inks, is required.

On the other hand, sublimation printing demands a sublimation printer that utilizes sublimation dyes to produce vibrant prints.

The Epson SureColor series is highly recommended for sublimation printing, offering precision and reliability.

Each printer type is tailored to specific heat transfer methods, ensuring optimal results for various materials and applications.

2. Vinyl Cutter (For Vinyl Heat Transfer)

Heat transfer vinyl (HTV) printing requires precision, and that’s where a specialized vinyl cutter comes in.

The xTool M1 Ultra, among the top vinyl cutters in the market, is known for its ability to cut vinyl with incredible accuracy, enabling the creation of intricate and desired designs.

Whether you’re working on T-shirts, bags, or custom accessories, the right blade cutter is essential for achieving clean edges and quality results in HTV printing.

From the cutter’s sharpness to its settings, the vinyl cutter plays a vital role in making sure the vinyl adheres perfectly when heat pressed onto the surface, resulting in a professional finish.

3. Heat Press

A heat press is a machine designed for applying both heat and pressure to transfer designs onto fabric.

It works by placing transfer paper and the fabric together, pressing them to ensure the design adheres properly to the material.

While a specialized machine is typically used for this, you can also use an everyday iron for simpler DIY projects, especially for vinyl projects.

The process guarantees the design stays intact and is perfectly transferred, offering a convenient method for home or small business applications.

Steps Of Custom Heat Transfer Printing

Following is the description of step involved in custom heat transfer printing:

Step 1: Preparation of a Design

The key to effective heat transfer printing starts with preparing the right design.

Whether you choose free designs available online or decide to create custom designs, graphic design software such as Adobe Illustrator, CorelDRAW, or Canva are ideal tools for this task.

It’s crucial to ensure that your design is high-resolution and properly sized for the project to ensure a successful transfer onto the fabric.

By focusing on these details, you set the foundation for a smooth and professional heat transfer printing process.

Step 2: Print it onto Transfer Paper

For a smooth heat transfer printing process, it’s essential to print your colored design onto the right type of transfer paper.

The transfer paper film you choose must be appropriate for the specific printer you’re using.

For example, when opting for sublimation printing, a sublimation printer combined with sublimation paper is the best choice for vivid results.

If you’re just starting out, vinyl heat transfer is an ideal option, offering simplicity while still delivering high-quality designs.

This method is perfect for beginners looking to get a feel for the process before diving into more advanced techniques.

Step 3: Cut the Design

When working with heat transfer vinyl (HTV), cutting the design from the vinyl sheet is a crucial step for achieving precise results.

For this, a blade cutter like the xTool M1 Ultra is highly recommended to ensure the cuts are sharp and accurate.

Whether you’re a beginner or experienced, this step gives your design the perfect shape before you apply it to the fabric, making sure the vinyl adheres as intended.

Step 4: Heat Press It

After printing your design onto transfer paper or cutting out vinyl designs, place it on the item you intend to decorate.

Preheating the heat press machine to the recommended temperature for your transfer material is crucial to ensure proper adhesion.

Protect your design with parchment paper and apply firm, even pressure during the pressing process.

Once the designated time is up, open the heat press carefully and remove the item, ensuring that your design is perfectly transferred onto the material.

Step 5: Peel and Finish

After completing the heat transfer process, it’s essential to peel the transfer paper or film while the design is still warm or cold, depending on your transfer type’s specific instructions.

Always check to ensure that the design has adhered properly, and that there are no missing areas or imperfections.

If needed, you can press it again with a Teflon sheet to achieve a smooth finish. This step ensures your design remains intact and professional-looking.

Conclusion

Conclusively, heat transfer printing gives a versatile and effective means of customization using items of vibrant and durable designs.

Considering the effective techniques produces high quality and ever-lasting outcomes.

Irrespective of the use of sublimation of vinyl, the process is effective to get required attention.

With practice, you can master the art of heat transfer printing for any project or business.

FAQs

Q1: What is heat transfer printing?

Heat transfer printing is a method of transferring a design onto a material using heat and pressure, often with specialized paper or vinyl.

Q2: Can I use any printer for heat transfer printing?

No, specific printers like sublimation printers or inkjet printers with the right transfer paper are required for heat transfer printing.

Q3: How long should I press the design with a heat press machine?

The pressing time depends on the material and transfer method, but typically it ranges from 30 seconds to 1 minute.

Q4: Is heat transfer printing durable?

Yes, if done correctly, heat transfer printing creates durable designs that can last through multiple washes and daily use.

Q5: Can I use heat transfer printing on any fabric?

Heat transfer printing works best on synthetic fabrics like polyester or cotton blends, but results may vary depending on the material.