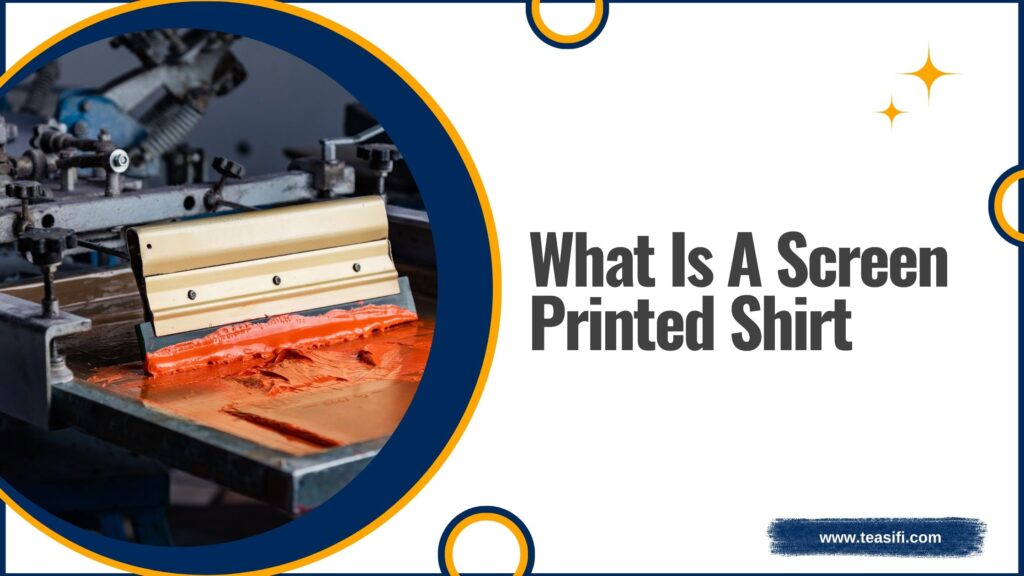

Screen printing, also referred to as silk screen printing or serigraphy, is a technique for transferring a stenciled design onto a flat surface using a mesh screen, ink, and a squeegee.

The method is widely popular in industries like fabrics, posters, canvases, and custom clothing, where bold and vivid colors with a tactile finish are needed.

The core idea involves creating a stencil that blocks certain areas of the mesh screen.

When ink is pressed through the open spaces using a squeegee, the desired design is imprinted onto the material below.

This process works on a variety of surfaces, including fabric, paper, wood, plastic, metal, and even glass.

Its ability to handle intricate and multicolored designs makes it a favorite among professionals and enthusiasts alike.

In this article, we will explore about the screen printing.

Table of Contents

ToggleWhy is Screen Printing Used?

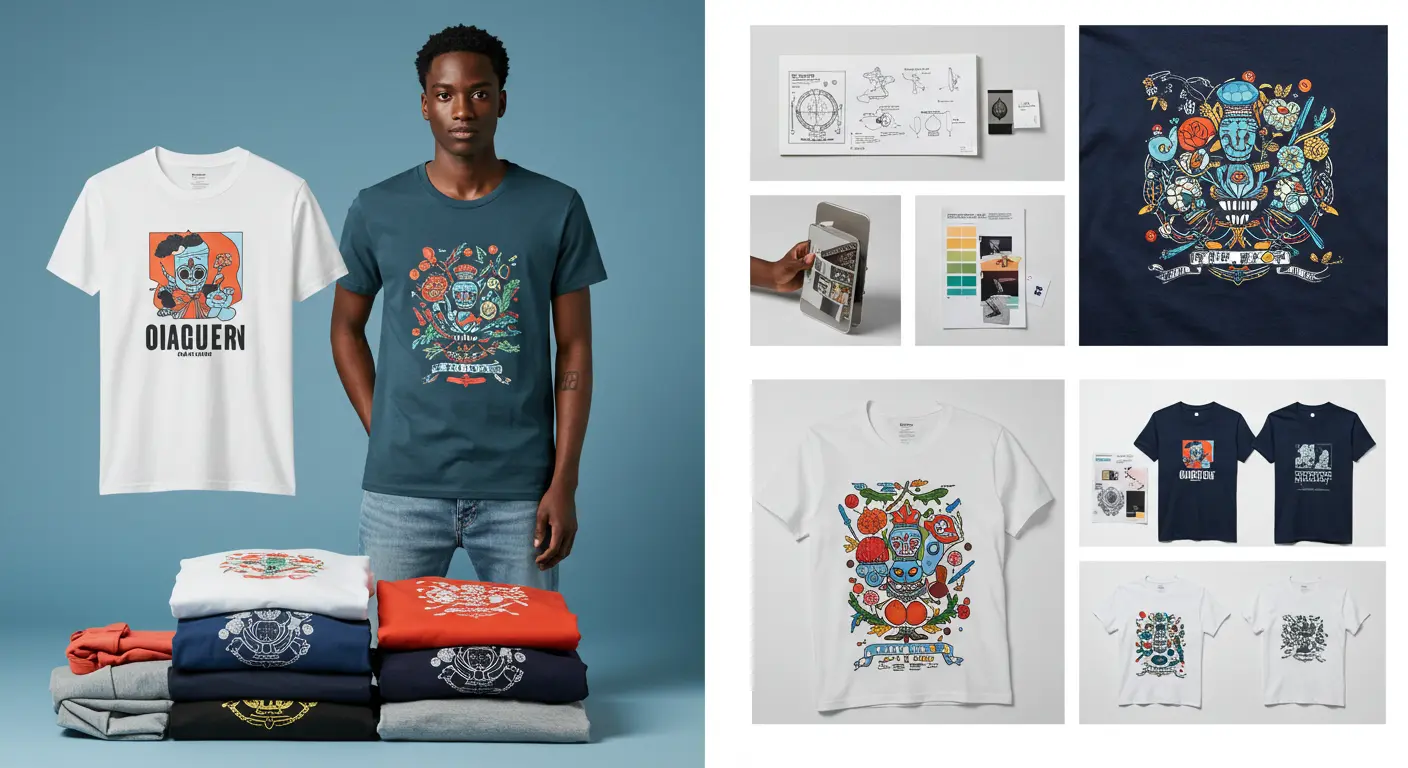

Screen printing is widely used because of its versatility, durability, and vibrant results.

This technique produces sharp prints with rich vivid colors, capable of handling layers and complex designs.

Whether for sports teams, work uniforms, or custom clothing, screen-printed designs are long-wearing and machine-washable, maintaining their intensity even after repeated use.

Unlike other printing methods like digital printing, screen printing can apply thick layers of ink to create textures, such as puff inks or glittery effects.

It is ideal for producing large batches of garments or personalized items at an affordable cost.

For businesses, its ability to replicate designs with precision and consistency makes it a go-to technique for large-scale projects.

The Screen Printing Process Step by Step

Step 1: The Design is Created

The process begins with creating the design, which is typically drawn or digitized using software.

A transparency or acetate sheet is used to carry the design. This step requires attention to detail, especially for multicolored designs, as each color layer will need its own stencil.

Step 2: The Screen is Prepared

Next, a mesh screen, traditionally made of silk but now often replaced by polyester fabrics, is tightly stretched over a frame. This fine mesh is crucial for creating intricate and accurate stencils.

Step 3: The Emulsion is Exposed

A light-sensitive emulsion is applied to the screen, coating it evenly.

Once dry, the design is placed on the screen and exposed to a specific shade of light. This hardens the emulsion where light touches, leaving the design area intact.

Step 4: The Emulsion is Washed Off, Creating the Stencil

The screen is washed with water to remove the unhardened emulsion, revealing the stencil. The open areas allow ink to pass through, while the rest of the screen remains blocked.

Step 5: The Item is Prepared for Print

The material whether fabric, paper, or plastic is placed on the printing press. Masking tape, screen blockers, or vinyl may be used to protect areas outside the design.

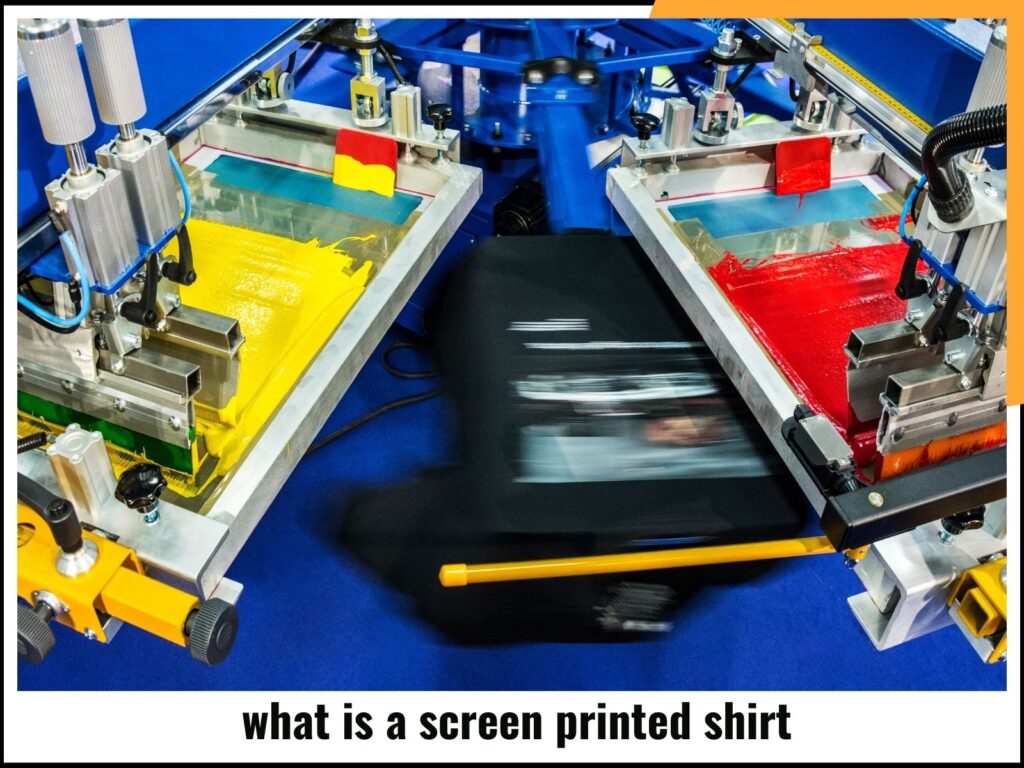

Step 6: The Ink is Pressed Through the Screen onto the Item

Using a squeegee, the ink is pressed firmly through the mesh screen, transferring the design onto the item. For multicolored designs, this step is repeated for each color layer, ensuring proper alignment.

Step 7: The Product is Dried, Checked, and Finished

The printed item is placed in a dryer to cure the ink, making it colourfast and long-lasting. Once dry, the design is checked for quality and consistency before being ready for use.

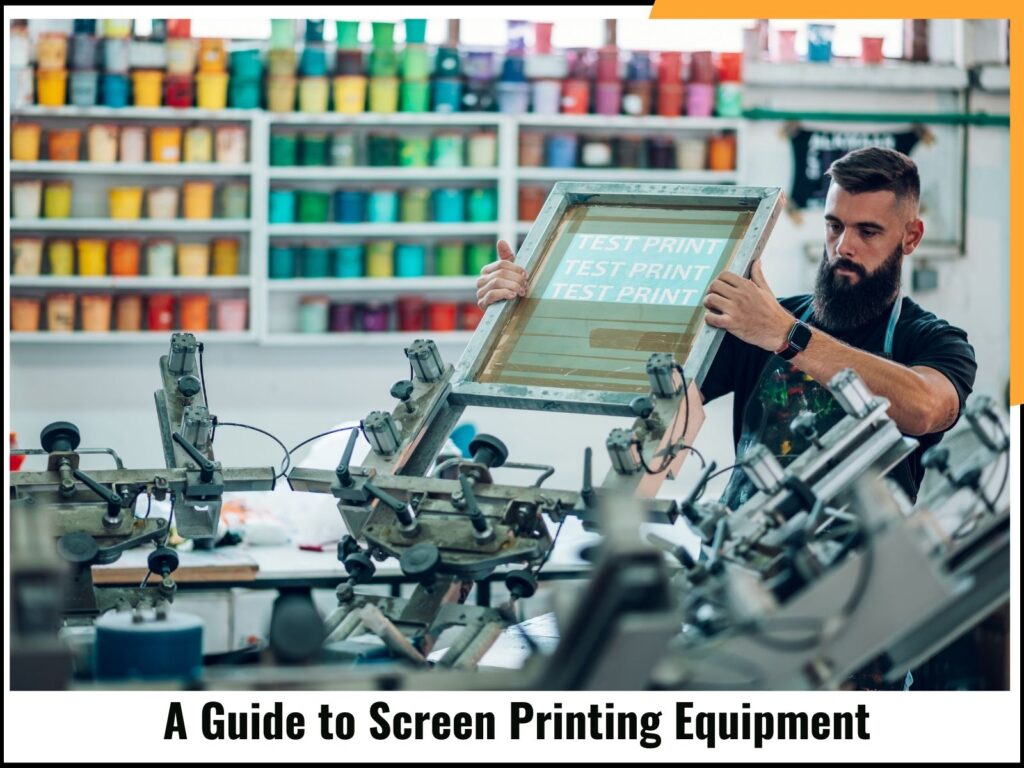

A Guide to Screen Printing Equipment

Screen Printing Press

The printing press is the backbone of the process. Options range from manual presses for small-scale work to automatic or rotary carousel printers for high-volume projects.

The Inks

Screen printing uses a variety of inks, including puff inks, texturised finishes, and glittery formulations. Choosing the right ink is essential for ensuring durability and vibrancy, especially on materials like polyester fabrics.

The Silk Screen

The silk screen, now often made from polyester, acts as the medium for the stencil. The quality of the mesh determines the level of detail the design can achieve.

The Squeegee

The squeegee is a rubber blade used to spread the ink evenly across the stencil. Proper technique is crucial for achieving sharp and clean prints.

The Washing Station

After printing, the screen is cleaned in the washing station using a power hose and cleaning fluid. Proper cleaning ensures the mesh screen can be reused for future designs.

Will Screen Printing Ink Wash Out?

When done properly, screen-printed designs are highly durable and resistant to washing. T

he curing process ensures the ink bonds to the material, making it machine-washable and long-lasting.

Using high-quality inks and equipment guarantees the design stays intact even on challenging materials like polyester fabrics.

What is the Difference Between Screen Printing and Digital Printing?

The key difference lies in the technique and finish. Screen printing uses a mesh screen to apply ink in layers, resulting in a vivid, textured design.

Digital printing, or DTG (Direct to Garment), involves applying CMYK pigments directly to the material, offering a smoother, softer feel but less texture and vibrancy compared to screen printing.

What’s the Difference Between Silk Screen Printing and Heat Transfer?

Silk screen printing involves creating a stencil and pressing ink directly onto the material, whereas heat transfer uses sublimation paper and heat to transfer a design.

While heat transfer is great for quick, small-batch projects, silk screen printing offers superior durability and vivid colors for large orders.

The History of Screen Printing

Originating centuries ago, screen printing gained prominence as an artistic medium in the 20th century.

Artists like Andy Warhol and Eduardo Paolozzi used it to create iconic works like the Marilyn Diptych.

Today, it remains a popular choice for both artistic and commercial applications, offering a balance of tradition and innovation.

FAQs !!

1. What is screen printing and how does it work?

Screen printing is a method used to transfer designs onto various materials, such as fabric, paper, and plastic, using a mesh screen.

The screen, coated with a stencil of the design, is placed on the surface, and ink is pushed through the mesh using a squeegee.

The ink only passes through areas of the screen not blocked by the stencil, leaving the design on the material.

This technique is highly versatile and can produce vibrant, long-lasting prints, making it popular for custom t-shirts, posters, and more.

2. What are the benefits of using screen printing?

Screen printing offers several key benefits, including high-quality, durable prints that can last longer than other methods like heat transfer.

It’s ideal for large runs of designs, as it becomes more cost-effective with volume.

Screen printing also allows for vibrant, opaque colors, which work well on dark fabrics or surfaces.

Plus, it supports various materials, including fabrics, glass, and wood, making it a versatile choice for businesses and creative projects.

3. How do I choose the right screen printing ink?

Choosing the right ink depends on the material you’re printing on and the type of design you want.

For fabric, plastisol inks are popular due to their vibrant colors and durability.

Water-based inks are another option, providing a softer feel and eco-friendliness.

If you’re printing on non-fabric materials like wood or plastic, special inks designed for those surfaces are needed to ensure long-lasting adhesion and color quality.

4. Can I use screen printing for small orders or one-off designs?

While screen printing is often associated with large orders, it’s possible to use it for smaller runs or even one-off designs.

However, it may not always be the most cost-effective option for just a few pieces due to setup costs.

For small-scale projects, digital printing or heat press may be better alternatives, but for higher volume, screen printing excels in providing cost efficiency, especially when repeating the same design across multiple items.

5. What are the common issues in screen printing and how do I fix them?

Some common screen printing issues include ink smudging, poor color quality, or uneven prints.

Smudging can be resolved by ensuring proper drying time between layers of ink and adjusting your press settings.

Poor color quality may be due to incorrect ink types or mesh screens that are too fine, which can be corrected by selecting the right combination for your material.

Uneven prints are often caused by improper pressure or uneven ink distribution, which can be fixed by adjusting your squeegee technique and press setup.

6. Is screen printing a good value for money?

Screen printing offers excellent value for money, especially for large orders.

While the setup process can be time-consuming, the cost per unit drops significantly with higher quantities.

This makes it a cost-effective choice for custom apparel, bulk orders, and other projects that require consistent, high-quality results.

It’s a durable, long-lasting method that ensures the design stays vibrant, making it a worthwhile investment for businesses and individuals needing high-volume prints.

7. How does screen printing compare to other printing methods?

Screen printing stands out for its durability, vibrant colors, and cost-effectiveness in high volumes.

Compared to methods like direct-to-garment (DTG) printing, screen printing is better for bulk orders and produces more vivid, long-lasting prints.

While DTG is more suitable for small runs or highly detailed designs, screen printing is the go-to for bold, solid colors and large print runs.

The choice depends on your specific needs, such as order size, budget, and design complexity.