Determination of screen tension is important for screen printers at all stages of the process irrespective of new or the experienced.

The most important point is that the resolution and determination of tension when it is low is important for understanding the time of retiring a screen from your inventory.

The process of screening naturally tolerates wear while impacting the usefulness of life. The most important thing is to determine what is a good tension for screen printing for the best management of tension during the process of screen printing.

Irrespective of tossing the matter, the determination and re-stretching of new one can serve effectively.

Judging the right action involves closely examining the tension and understanding how it affects the final print.

Screen printers who prioritize maintaining the right tension not only extend the life of their screens but also enhance the quality of their work.

Table of Contents

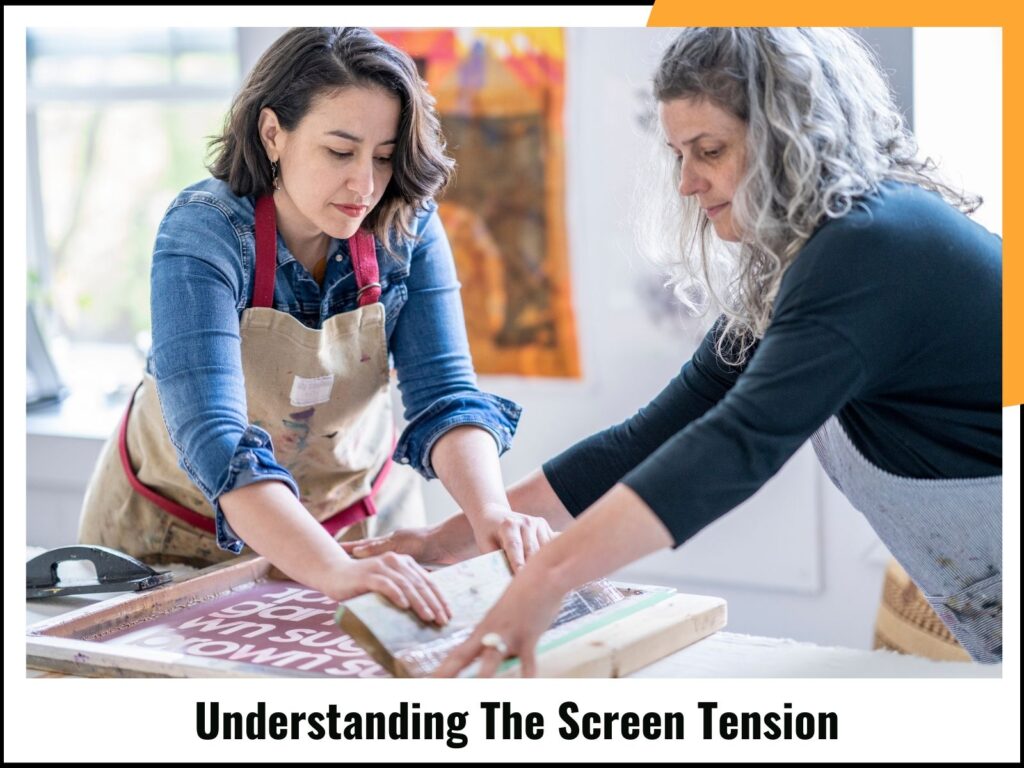

ToggleUnderstanding The Screen Tension

Screen tension plays a critical role in achieving consistent print quality, and understanding how the mesh interacts with the screen frame is essential.

High tension ensures the mesh stays taut, while low tension leaves it slack, leading to issues like rough prints or blurriness.

When using a squeegee on a screen with improper tension, the mesh may shift, causing misalignment and impacting the overall result, especially in detailed or multi-color prints.

Proper tension allows the mesh to snap off the ink cleanly, avoiding uneven edges and maintaining precision.

By keeping your screens stretched correctly and monitoring their condition regularly, you can prevent significant problems and maintain the crucial balance required for professional-quality prints.

WHEN TENSION IS TOO LOW

Achieving the right tension is crucial for maintaining stability during printing.

A screen with low tension often leads to issues like distorted or elongated images and misaligned registration marks, especially in multicolor designs.

Stability ensures the screen doesn’t move, and a proper snap-off or peel-off action behind the squeegee avoids sticking to the print or shirt.

If the screen fails to perform as needed, increasing off contact might help, but excessive adjustments—such as exceeding 1/8th or approaching ¼ inch—may signal the need to replace the screen.

Reclaiming a screen or repeated use naturally contributes to wear and tear, resulting in tension loss over time, which further highlights the importance of consistent monitoring and maintenance.

Tension Across Different Screen Types

The type of frame you use directly impacts tension stability and print quality, making it essential to match the right screen type to your needs.

Static aluminum frames, while common and dependable, tend to lose tension over time and offer no adjustment capability.

For more adaptability, eco frames or click frames allow easy replacement of mesh panels, ensuring consistent tension and maintaining high print quality even as wear occurs.

Roller frames are the pinnacle of performance in screen printing, providing the ability to adjust tension as needed to keep screens tight and prints sharp.

Each frame type serves a unique purpose, so understanding how tension changes over time with your chosen frame can greatly improve your results.

Practical Tips For Tension Management

Managing screen tension effectively ensures consistent print quality and extends the life of your tools.

A tension meter provides an exact reading, enabling precise adjustments to maintain optimal screen tension and avoid costly errors.

Alternatively, you can rely on the sound check method by tapping the mesh; a bass drum sound indicates low tension, while a snare drum sound signals it’s in good shape.

Adjusting off-contact by increasing the distance between the screen and the substrate can temporarily compensate for lower tension, though frequent adjustments may mean it’s time to re-stretch or replace the screen.

Taking these steps ensures your prints remain sharp and professional, reducing the need for temporary fixes and protecting your investment.

Conclusion

Achieving the right screen tension is essential to maintaining a smooth printing process and producing prints that stand out with sharp details.

If your registration feels off or you’re struggling to get the clarity you expect, it might be time to check your screens.

Proper tension levels not only extend the life of your screens but also ensure that every print you produce reflects the highest quality standards.

By focusing on maintaining this backbone of the printing process, you can avoid inconsistencies and guarantee professional results every time.

FAQs

Q1: What is screen tension in printing?

Screen tension refers to the tightness of the mesh stretched over the printing frame. Proper tension ensures even ink distribution and high-quality prints.

Q2: Why is maintaining screen tension important?

Maintaining correct screen tension ensures sharp, precise prints, improves registration accuracy, and prolongs the screen’s lifespan, reducing the need for frequent replacements.

Q3: How can I measure screen tension?

You can measure screen tension using a tension meter for exact readings or perform a sound test by tapping the mesh—a snare drum sound indicates good tension, while a bass drum sound signals low tension.

Q4: What causes screen tension to drop?

Factors like repeated printing, environmental humidity, mesh degradation, and improper handling can lead to tension loss over time.

Q5: Can I adjust tension on all screen frames?

No, only frames like roller frames allow tension adjustments. Static aluminum frames and eco frames typically require mesh replacement instead.

Q6: What’s the best way to maintain screen tension?

Regularly check the tension using a meter or sound test, and re-stretch or replace the mesh as necessary to keep print quality consistent.

Q7: Does tension affect print quality?

Yes, incorrect tension causes blurry or uneven prints, ink smudging, and poor registration, directly impacting overall printing quality.