When it comes to customizing garments with designs, logos, or slogans, the debate between iron-on printing and screen printing often arises. Both methods offer unique advantages, catering to different needs based on factors like durability, cost, speed, and the complexity of the design.

Screen printing, with its ability to produce vivid colors and long-lasting results, is ideal for bulk printing and professional projects.

On the other hand, iron-on printing shines in its simplicity, affordability, and suitability for DIY enthusiasts or smaller, more intricate orders. Understanding the strengths of each method helps in making an informed decision tailored to your customization goals.

Table of Contents

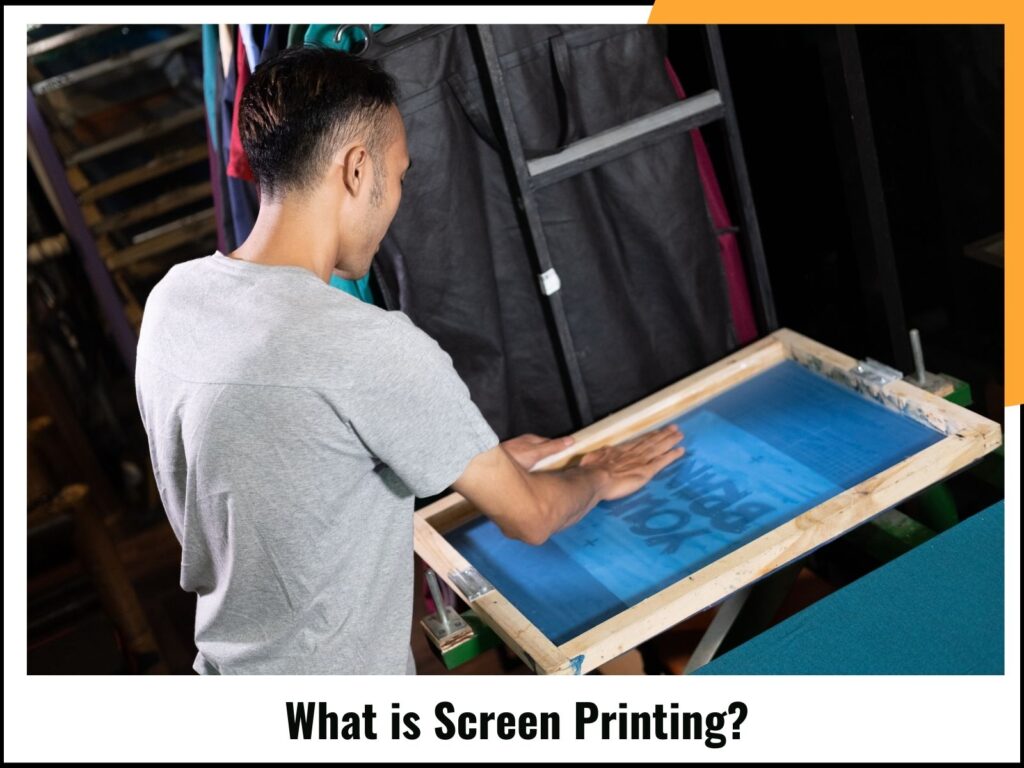

ToggleWhat is Screen Printing?

Screen printing, often called silk screening, is a versatile printing technique that transfers designs onto fabric using a mesh screen, a stencil, and ink.

The process involves pressing the ink through the screen with a squeegee, leaving a bold and raised print. This method excels in creating vivid colors and intricate designs that stand out on both light-colored fabric and dark-colored fabric.

However, it can be time-consuming due to the setup required for multiple stencils and the chemicals involved in cleaning the equipment. Whether you’re customizing garments for branding or personal use, this method ensures high-quality and durable results, making it ideal for bulk printing.

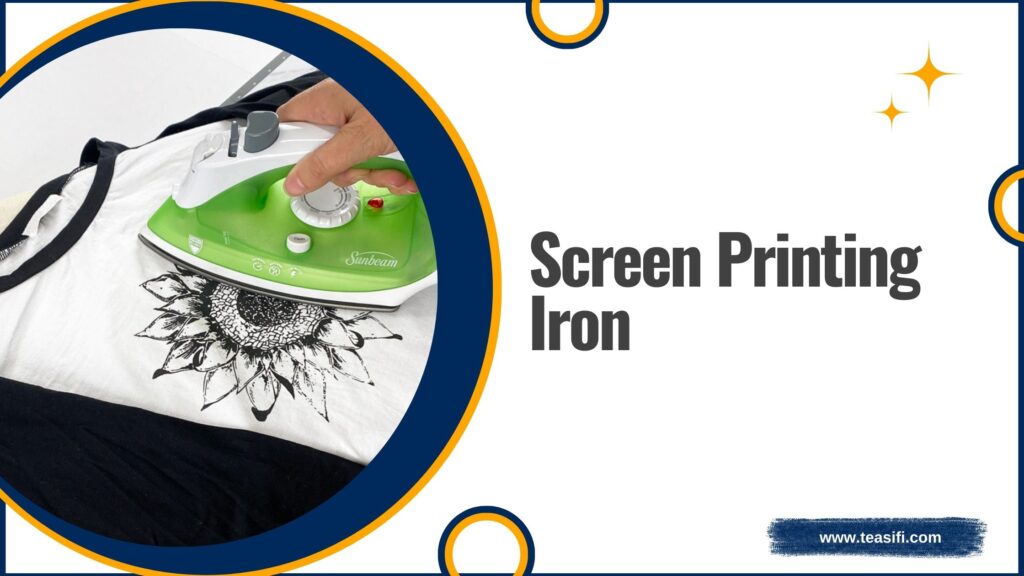

What is Heat-Transfer/Iron-On Printing?

Iron-on printing, also known as heat transfer, uses a heat press machine to apply designs onto fabric. This technique involves two approaches: vinyl heat transfer and digital print.

The vinyl method involves cutting adhesive-coated material into shapes or letters, which are then heat-pressed onto the garment. Digital heat transfer prints designs onto special paper, transferring them to the fabric through heat and pressure.

While this method offers sharp quality and a plastic look, its durability is limited compared to screen printing, as repeated washing may lead to cracking or fading.

Perfect for DIY enthusiasts or small orders, iron-on printing offers an affordable and cost-efficient way to achieve personalized designs.

Screen Printing vs. Heat-Transfer: Which is Better?

Choosing between screen printing and heat transfer depends on your needs. For durability, vivid colors, and large runs, screen printing is superior due to its ability to produce long-lasting, high-resolution designs.

However, if you prioritize speed, flexibility, and cost-efficiency for smaller orders or complex designs, iron-on printing is a practical choice.

While screen printing is better for bulk printing and branding, heat transfer shines in creating intricate images on light fabric.

Cost Comparison

Iron-on printing is generally more affordable for smaller orders or DIY projects, requiring minimal equipment and materials.

In contrast, screen printing involves higher setup fees but becomes more economical for larger orders due to its efficiency in producing multiple items.

For events like a charity event or professional branding, screen printing might be the better investment if you’re printing over 100 pieces.

Quality

For long-lasting bold colors and vibrant designs, screen printing takes the lead. The ink adhesion ensures the design becomes part of the fabric, maintaining its color resolution even after repeated washing.

On the other hand, iron-on printing offers high-resolution results initially but tends to lose its sharp quality over time.

Durability

Screen printing offers unmatched durability, with designs that resist cracking and fading, making them perfect for frequent use.

In comparison, iron-on printing may only last up to 50 washes before noticeable wear occurs. For garment customization that stands the test of time, screen printing is the go-to option.

Difficulty

The screen printing process can be tedious, requiring precise setup and the use of advanced machines. Conversely, iron-on printing is simpler and more accessible, making it an excellent choice for beginners or quick projects.

With a heat press machine, a design, and the right materials, you can start printing in no time.

Speed

While the setup for screen printing is more labor-intensive, the method can produce over 100 prints per hour once the process begins. Iron-on printing, however, works one garment at a time, making it less time-efficient for large orders but ideal for quick, small batches.

Multi-Colored Designs

Screen printing is better suited for multi-colored designs, offering vibrant, layered prints with exceptional color retention.

However, for simple or single-color designs, iron-on transfers can deliver crisp edges with minimal effort. When working with intricate designs or photographs, screen printing provides superior results.

Conclusion

Choosing between screen printing and iron-on printing ultimately depends on your priorities, such as cost-efficiency, quality, and the desired outcome. For bulk orders and designs requiring bold colors and durability, screen printing is the top choice.

However, for quick, cost-effective projects with a personal touch, iron-on printing offers unmatched versatility and ease of use.

Whether you’re a hobbyist or a professional, both methods provide effective solutions for garment customization, ensuring your designs leave a lasting impression.

FAQs

Q1. What’s the difference between iron-on and screen printing?

Iron-on designs are created using heat transfer methods where a pre-designed image is pressed onto fabric with heat. Screen printing, on the other hand, involves using stencils and ink to print directly onto the fabric. Iron-on is often more DIY-friendly and faster for small quantities, while screen printing is ideal for large batches due to its durability and vibrant color retention.

Q2. Which is better for T-shirts: iron-on or screen printing?

It depends on your needs. Iron-on transfers are great for custom, one-off designs or small orders because they are cost-effective and simple to use. Screen printing excels for bulk orders, offering a more professional finish and longer-lasting results, especially for frequent wear and washing.

Q3. Does iron-on last as long as screen printing?

No, iron-on designs generally do not last as long as screen-printed ones. Over time, iron-on transfers can crack or peel, especially with frequent washing. Screen printing uses ink that bonds directly to the fabric, making it more durable and resistant to fading or damage.

Q4. Can I use iron-on for dark fabrics?

Yes, but you’ll need special iron-on transfers designed for dark fabrics. These transfers have an opaque backing to ensure the design stands out against darker materials. Screen printing, however, naturally works well on dark fabrics due to its layering capabilities.

Q5. Is screen printing more expensive than iron-on?

Screen printing is often more expensive upfront because of setup costs, especially for small orders. However, for larger quantities, it becomes more cost-effective per item. Iron-on is cheaper for smaller projects but can become costly for bulk production due to the time and effort required.

Q6. What kind of fabric works best for iron-on transfers?

Iron-on transfers work best on cotton and cotton-blend fabrics, as these materials can withstand the heat needed for application. Avoid synthetic fabrics like polyester unless using specialized transfers designed for them. Screen printing, on the other hand, is versatile and works well on most fabrics.

Q7. Are iron-on transfers DIY-friendly?

Absolutely! Iron-on transfers are perfect for DIY projects because they only require a heat source, like a household iron or heat press. This makes them accessible for personalizing clothing, tote bags, and more without specialized equipment.

Q8. Does screen printing require professional equipment?

Yes, screen printing typically requires professional equipment, including screens, ink, and a drying setup. While it is possible to create small-scale screen printing projects at home, achieving high-quality results often requires professional tools and experience.

Q9. How do I care for iron-on designs to make them last longer?

To extend the life of iron-on designs, wash the garment inside out in cold water on a gentle cycle. Avoid high heat in the dryer, and never iron directly over the design. For screen-printed garments, similar care ensures longevity, though they’re generally more resistant to wear.

Q10. Which method is more eco-friendly: iron-on or screen printing?

Screen printing can be more eco-friendly, especially when using water-based inks and reusable screens. Iron-on transfers often involve single-use materials and can generate more waste, though some brands now offer eco-friendly transfer options.

Q11. Can I combine iron-on and screen printing in one design?

Yes, combining both methods can be a creative way to achieve unique designs. For instance, you might use iron-on for intricate details or personalized elements and screen printing for the main design. Just ensure compatibility between the methods for the best results.

Q12. What is the best option for starting a custom apparel business?

For a small-scale custom apparel business, iron-on transfers are a great way to start due to their low initial cost and flexibility. As your business grows, investing in screen printing can help you handle larger orders and provide a more professional finish.

Q13. Are there any warranties or guarantees for iron-on vs. screen printing supplies?

This depends on the manufacturer or service provider. Most iron-on transfer sheets come with a satisfaction guarantee, while screen printing equipment or services may offer warranties for equipment or reprints for errors. Always check the vendor’s return and warranty policies.

Q14. How do I troubleshoot issues with iron-on transfers?

If your iron-on transfer doesn’t adhere well, check the temperature, pressure, and time settings during application. Ensure the fabric is clean and wrinkle-free, and use a firm, flat surface. For peeling designs, reapply heat with a protective sheet over the transfer.

Q15. Which method offers more vibrant colors?

Screen printing generally offers more vibrant and durable colors because the ink penetrates the fabric and can be layered for opacity. Iron-on designs may fade more quickly, though high-quality transfers can still provide vivid results.